Kedu ihe mgbakwunye mgbochi iyi akpụkpọ ụkwụ na-eme ka ọ ghara iguzogide mmetọ akpụkpọ ụkwụ?

Kedu ihe mgbakwunye mgbochi iyi akpụkpọ ụkwụ na-eme ka ọ ghara iguzogide mmetọ?,

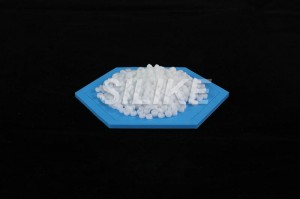

iguzogide abrasion, ihe mgbakwunye mgbochi iyi, ụkwụ akpụkpọ ụkwụ, Ihe mgbakwunye Silicone,

Nkọwa

NM-2T bụ usoro pelletized nwere 50% UHMW Siloxane polymer gbasaara na resin EVA. Ọ bụ ụdị emelitere nke NM-2 ochie anyị nke Anti-abrasion masterbatch nwere Siloxane dị mma na ọdịnaya siloxane dị elu. Emepụtara ya nke ọma maka sistemụ resin dakọtara na EVA ma ọ bụ EVA iji melite iguzogide abrasion ihe ikpeazụ ma belata uru abrasion na thermoplastics.

Ma e jiri ya tụnyere ihe mgbakwunye silicone / siloxane dị obere, dị ka mmanụ silicone, mmiri silicone ma ọ bụ ụdị ihe mgbakwunye nhicha ndị ọzọ, a na-atụ anya na SILIKE Anti-abrasion Masterbatch NM-2T ga-enye ihe onwunwe iguzogide nsị ka mma na-enweghị mmetụta ọ bụla na ike na agba.

Ntọala Ndị Dị Mkpa

| Aha | NM-2T |

| Ọdịdị | Mpellet ọcha |

| Ọdịnaya nke ihe ndị dị n'ime ya | 50 |

| Ntọala resin | EVA |

| Ọnụọgụ % | 0.5~5% |

| Ngwa | EVA, PVC naanị |

uru

(1) Mmeziwanye iguzogide nchacha yana mbelata uru nchacha

(2) Nye arụmọrụ nhazi na ọdịdị ihe ikpeazụ

(3) Ọ dịghị mma maka gburugburu ebe obibi

(4) Enweghị mmetụta na ike na agba

(5) Dị irè maka ule DIN, ASTM, NBS, AKRON, SATRA, GB

Ngwa

(1) Akpụkpọ ụkwụ EVA

(2) Akpụkpọ ụkwụ PVC

(3) Ngwakọta EVA

(4) Plastik ndị ọzọ dakọtara na EVA

Otu esi eji ya

SILIKE A pụrụ iji SILIKE mee ihe dịka ihe e ji ebu resin nke ha ji mee ya. A pụrụ iji ya mee ihe n'usoro ngwakọta agbaze agbaze nke oge ochie dịka ihe na-eme ka ihe na-agbaze otu/mkpụrụ osisi abụọ, ihe e ji etinye ihe n'ime ya. A na-atụ aro ka e jiri ihe ndị a na-akpọ "single/twin skru molding" mee ihe.

Kwado usoro onunu ogwu

Mgbe etinyere ya na EVA ma ọ bụ thermoplastic yiri ya na 0.2 ruo 1%, a na-atụ anya ka nhazi na mmiri resin ka mma, gụnyere ijupụta ebu ka mma, obere ike extruder, mmanụ dị n'ime, mwepụta ebu na mmepụta ngwa ngwa; Na ọkwa mgbakwunye dị elu, 2 ~ 10%, a na-atụ anya ka njirimara elu ka mma, gụnyere mmanụ ọkụ, mmịpụta, obere coefficient nke esemokwu na nnukwu mar/scratch na abrasion resistance.

Ngwugwu

25Kg / akpa, akpa akwụkwọ aka ọrụ

Nchekwa

Debe ya n'ebe dị jụụ ma ikuku na-abata nke ọma.

Ndụ nchekwa

Njirimara mbụ ahụ na-adịgide ruo ọnwa iri abụọ na anọ site na ụbọchị mmepụta, ọ bụrụ na echekwara ya na nchekwa akwadoro.

Chengdu Silike Technology Co., Ltd bụ onye nrụpụta na onye na-eweta ihe eji eme silicone, onye raara onwe ya nye na nyocha na nhazi nke njikọta nke Silicone na thermoplastics maka afọ 20.+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnSilicone additives are used to make shoe soles more abrasion resistant because they create a protective layer on the surface of the sole. This layer helps to reduce the amount of wear and tear that the sole experiences, making it more durable and longer lasting. Silicone additives also help to reduce the amount of friction between the sole and the ground, which can help to reduce the amount of wear and tear that the sole experiences.

Mgbakwunye Silicone n'efu na ihe nlele Si-TPV karịrị akara 100

Ụdị ihe atụ

$0

- 50+

Ọkwa Silicone Masterbatch

- Iri+

Ọkwa Silicone ntụ ntụ

- Iri+

akara mmụta mgbochi ọkọ

- Iri+

Akara ngosi Anti-abrasion Masterbatch

- Iri+

akara Si-TPV

- 8+

Ihe ndị dị na Silicone Wax

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

WhatsApp

-

Elu

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur