N'oge a ebe ụkpụrụ nchekwa na iwu dị oke mkpa, mmepe nke ihe ndị na-eguzogide mgbasa nke ọkụ aghọwo akụkụ dị mkpa nke ụlọ ọrụ dị iche iche. N'ime ihe ọhụrụ ndị a, ihe ndị na-egbochi ire ọkụ apụtala dị ka ngwọta dị elu iji mee ka iguzogide ọkụ nke polima dịkwuo mma.

Ịghọta Gịnị bụ ihe ndị mejupụtara Masterbatch nke na-egbochi ọkụ?

Ngwakọta masterbatch nke na-egbochi ọkụ bụ usoro pụrụ iche e mere iji nye polymers ihe ndị na-eguzogide ọkụ. Ngwakọta ndị a nwere resin ebu, nke na-abụkarị otu polymer ahụ dị ka ihe ndabere, na ihe mgbakwunye na-egbochi ọkụ. Resin ebu na-eje ozi dị ka ihe eji ekesa ihe ndị na-egbochi ọkụ n'ime matrix polymer.

Ihe mejupụtara ihe ndị na-egbochi ire ọkụ:

1. Resin onye na-ebu ibu:

Resin ebu ibu na-emepụta akụkụ kachasị nke masterbatch ma a na-ahọrọ ya dabere na ndakọrịta ya na polymer isi. Resin ebu ibu ndị a na-ahụkarị gụnyere polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), na thermoplastics ndị ọzọ. Nhọrọ nke resin ebu ibu dị oke mkpa iji hụ na mgbasa dị irè na ndakọrịta na polima ebumnuche.

2. Ihe mgbakwunye na-egbochi ire ọkụ:

Ihe mgbakwunye ihe mgbochi ọkụ bụ ihe ndị na-arụ ọrụ na-egbochi ma ọ bụ na-egbu oge mgbasa nke ọkụ. N'ikwu ya n'ụzọ dị mfe, ihe mgbochi ọkụ nwere ike ịbụ ihe mmeghachi omume ma ọ bụ ihe mgbakwunye. Enwere ike kewaa ihe mgbakwunye ndị a n'ime ụdị dị iche iche, gụnyere ihe ndị e ji halogen mee, ihe ndị sitere na phosphorus, na ihe ndị na-ejupụta mineral. Nkebi ọ bụla nwere usoro pụrụ iche nke ya iji gbochie usoro ọkụ.

2.1 Ihe ndị e ji Halogen mee: Ihe ndị e ji brominated na chlorine mee na-ewepụta ihe ndị na-akpata halogen n'oge ọkụ, nke na-egbochi mmeghachi omume nke usoro ọkụ.

2.2 Ngwakọta ndị e ji phosphorus mee: Ngwakọta ndị a na-ewepụta phosphoric acid ma ọ bụ polyphosphoric acid n'oge ọkụ, na-emepụta oyi akwa nchebe nke na-egbochi ire ọkụ.

2.3 Ihe ndị na-eme ka ihe dị n'ime ala dị ka aluminum hydroxide na magnesium hydroxide na-ewepụta uzuoku mmiri mgbe a na-ekpughere ya n'ọkụ, na-eme ka ihe ahụ jụọ oyi ma na-agbaze gas ndị na-ere ọkụ.

3. Ihe ndị na-ejupụta na ihe ndị na-eme ka ihe sie ike:

A na-etinye ihe njupụta, dị ka talc ma ọ bụ calcium carbonate, iji melite akụrụngwa nke ihe mejupụtara masterbatch. Ihe ndị na-eme ka ihe sie ike na-eme ka ike, ike, na nkwụsi ike nha dịkwuo mma, na-enyere aka na arụmọrụ zuru oke nke ihe ahụ.

4. Ihe ndị na-eme ka ihe sie ike:

A na-etinye ihe ndị na-eme ka ihe sie ike iji gbochie mmebi nke matrix polymer n'oge nhazi na ojiji. Dịka ọmụmaatụ, ihe ndị na-egbochi oxidants na ihe ndị na-eme ka ihe kwụsie ike na UV na-enyere aka ịnọgide na-enwe ezi uche nke ihe ahụ mgbe e tinyere ya n'ihe ndị metụtara gburugburu ebe obibi.

5. Agba na agba:

Dabere na ojiji e ji mee ya, a na-agbakwụnye agba na agba iji nye agba ụfọdụ na ihe mejupụtara masterbatch ahụ. Ihe ndị a nwekwara ike imetụta àgwà mma nke ihe ahụ.

6. Ihe ndị na-eme ka mmadụ kwekọọ:

N'ọnọdụ ebe ihe na-egbochi ọkụ na matrix polymer anaghị ekwekọ nke ọma, a na-eji ihe ndị na-eme ka ihe kwekọọ. Ihe ndị a na-eme ka mmekọrịta dị n'etiti ihe ndị ahụ ka mma, na-akwalite mgbasa nke ọma na arụmọrụ zuru oke.

7. Ihe ndị na-egbochi anwụrụ ọkụ:

A na-etinye ihe ndị na-egbochi anwụrụ ọkụ, dị ka zinc borate ma ọ bụ molybdenum compounds, mgbe ụfọdụ iji belata mmepụta anwụrụ ọkụ n'oge ọkụ, ihe dị mkpa a na-atụle n'ọrụ nchekwa ọkụ.

8. Ihe mgbakwunye maka nhazi:

Ihe enyemaka nhazi dịka mmanụ nandị na-ekesa iheNgwa ndị a na-eme ka usoro mmepụta ahụ dị mfe. Ihe mgbakwunye ndị a na-eme ka nhazi dị mfe, gbochie njikọta, ma na-enyere aka inweta mgbasa otu ụdị nke ihe ndị na-egbochi ire ọkụ.

Ihe ndị a niile bụ akụkụ niile nke ihe ndị na-egbochi ire ọkụ, ebe ijide n'aka na nkesa nke ihe ndị na-egbochi ire ọkụ n'ime matrix polymer bụ akụkụ dị oke mkpa nke arụmọrụ ha. Mgbasa ozi na-ezighi ezi nwere ike ibute nchebe na-adịghị mma, mmebi ihe onwunwe, na mbelata nchekwa ọkụ.

Ya mere, ihe ndị na-egbochi ọkụ na-achọkarị ihe ndị na-egbochi ọkụihe na-agbasaiji dozie nsogbu ndị metụtara mgbasa otu nke ihe ndị na-egbochi ire ọkụ n'ime matrix polymer.

Karịsịa n'akụkụ sayensị polymer siri ike, ọchịchọ maka ihe ndị na-egbochi ọkụ dị elu nwere njirimara arụmọrụ ka mma akpalila ihe ọhụrụ na ihe mgbakwunye na ihe ndị na-agbanwe agbanwe. N'ime ngwọta ndị na-eduga,ndị na-ekesa ọbara ọbaraApụtala dị ka ndị isi egwuregwu, na-edozi nsogbu nke inweta mgbasa kachasị mma na usoro nhazi nke Flame Retardant Masterbatch.

As ndị na-ekesa ọbara ọbaradozie nsogbu a site n'ịkwalite nkesa zuru oke na otu nha nke ihe mgbochi ọkụ n'ime ogige masterbatch niile.

Tinye Hyperdispersant SILIKE SILIMER 6150—otu ụdị ihe mgbakwunye ndị na-agbanwe ọdịdị nke usoro ihe mgbochi ọkụ!

E mepụtara SILIKE SILIMER 6150 iji gboo mkpa pụrụ iche nke ụlọ ọrụ polymer, Ọ bụ wax silicone agbanwere agbanwe. Dịka iheihe na-ekesa ọbara dị irè, na-enye ngwọta maka ihe ịma aka ndị metụtara inweta mgbasa ozi kachasị mma na, n'ihi ya, nchekwa ọkụ kacha mma.

A na-atụ aro ka ejiri SILIKE SILIMER 6150 mee ihe makamgbasa nke agba na ihe ndị na-ejupụta ihe na organic na inorganic, ihe ndị na-egbochi ọkụ na thermoplastic masterbatch, TPE, TPU, thermoplastic elastomers ndị ọzọ, na ngwa ndị mejupụtara ya. Enwere ike iji ya na ọtụtụ polymers thermoplastic gụnyere polyethylene, polypropylene, polystyrene, ABS, na PVC.

SILIKE SILIMER 6150, uru dị mkpa nke ihe ndị na-egbochi ire ọkụ

1. Meziwanye mgbasa nke ihe na-egbochi ire ọkụ

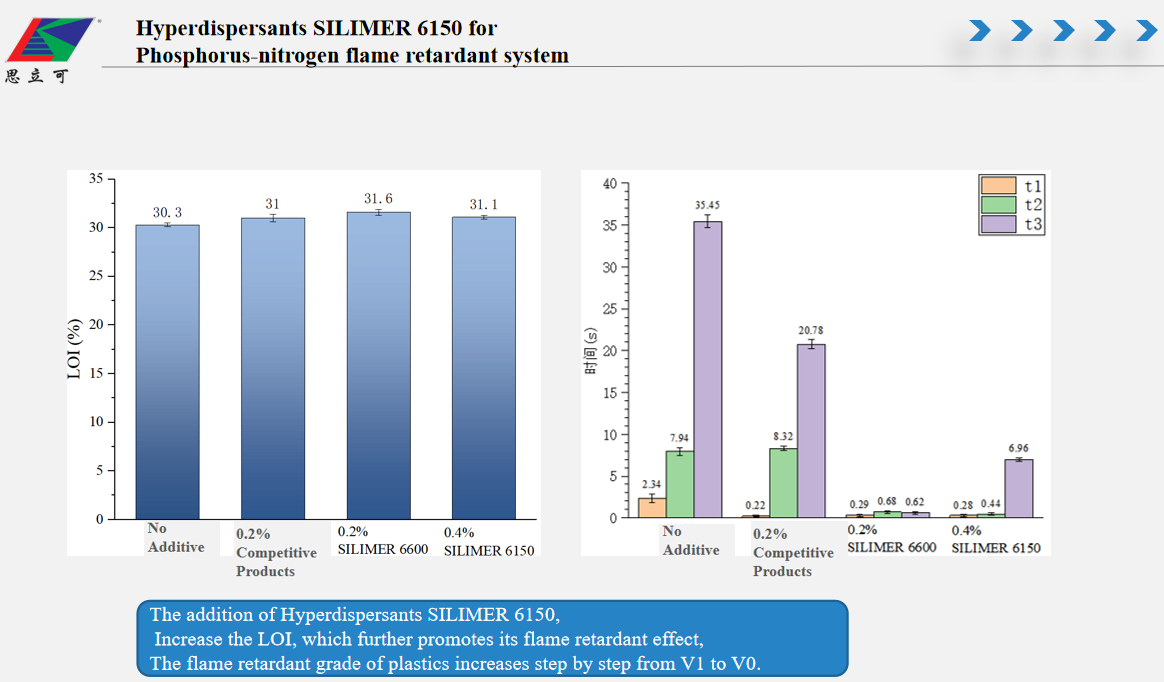

1) Enwere ike iji SILIKE SILIMER 6150 yana masterbatch phosphorus-nitrogen flame-retardant, na-eme ka mmetụta nke ire ọkụ nke ire ọkụ dịkwuo mma. Na-eme ka LOI dịkwuo elu, ire ọkụ g.rade nke plastik na-abawanye site na V1 ruo V0.

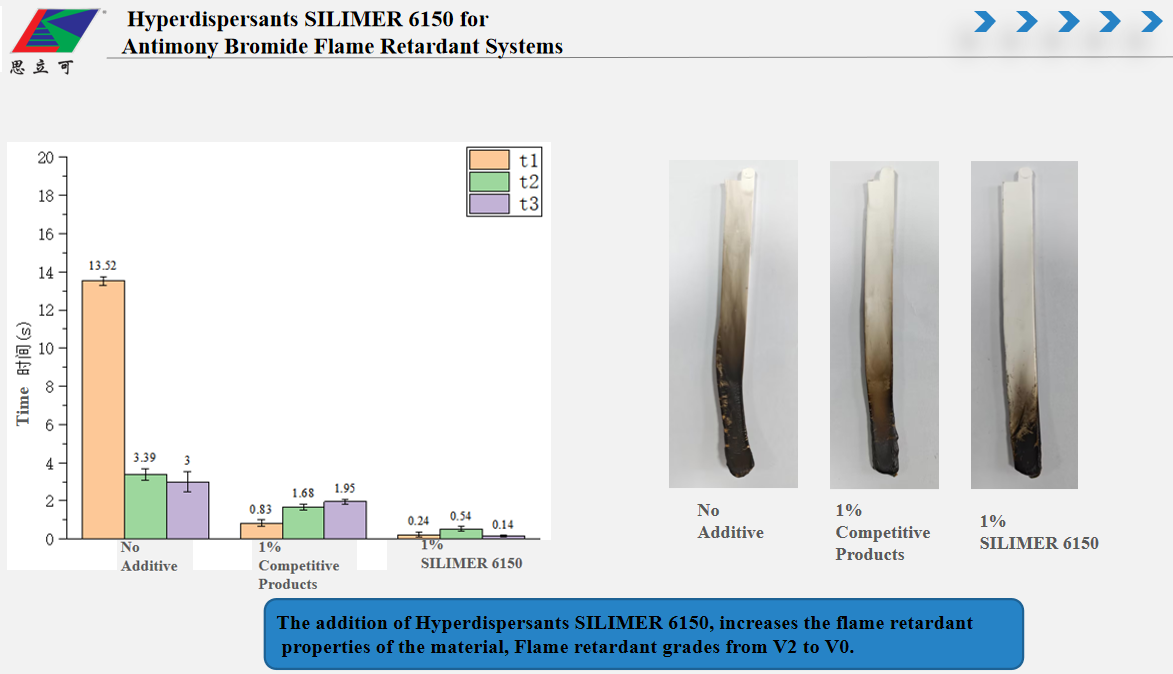

2) SILIKE SILIMER 6150 nwere ezigbo njikọ aka na-egbochi ire ọkụ na Antimony Bromide Flame Retardant Systems, ọkwa ihe na-egbochi ire ọkụ site na V2 ruo V0.

2. Meziwanye mma na ịdị nro nke ngwaahịa (COF dị ala)

3. Ọkwa mmiri agbaze na mgbasa nke ihe ndị na-ejupụta ihe ka mma, mwepụta ebu na arụmọrụ nhazi ka mma

4. Ike agba ka mma, enweghị mmetụta ọjọọ na ihe ndị dị n'ime ya.

Kpọtụrụ SILIKE ka ị hụ ka SILIMER 6150 Hyperdispersant nwere ike isi nyere ndị na-emepụta ihe aka n'ịmepụta ihe ndị na-egbochi ire ọkụ na thermoplastics ọhụrụ!

Oge ozi: Ọktoba-23-2023